Past CSIRO Extrusion Projects

Discover how CSIRO’s extrusion capabilities have helped companies turn initial ideas into real-world products.

v2food

In 2019, CSIRO collaborated with Jack Cowin’s Competitive Foods Australia and Main Sequence Ventures to establish v2food. CSIRO provided extensive R&D support to expediate the development and launch of their plant-based burger patties and mince. This support including long-term hire of the pilot-scale extruder module within the CSIRO Food Innovation Centre for continuous production of texturised vegetable protein (TVP) products.

Nutri V

Nutri V – an Australian start-up originating from the farming enterprise Fresh Select – collaborated with CSIRO to transform surplus vegetables into vegetable powders. These powders serve as key ingredients in the creation of Nutri V Goodies, a line of vegetable-based extruded snacks. CSIRO extrusion technology was pivotal in helping Nutri V turn farm waste into new food products.

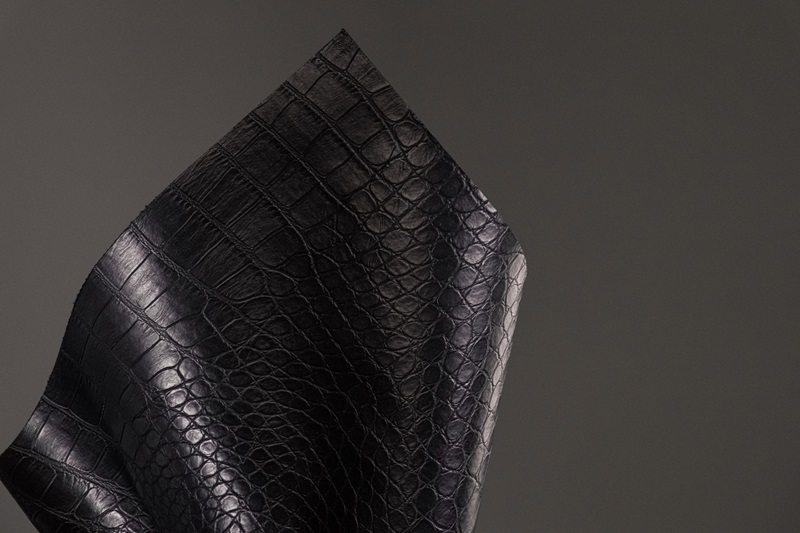

Alt Leather

CSIRO researchers assisted Alt Leather – a Melbourne-based start-up – in developing a 100% bio-based leather alternative by providing access to specialised extrusion equipment and expertise through the Kick-Start program. This support enabled the company to refine and scale their material production processes. Additionally, participation in CSIRO’s RISE Accelerator program facilitated connections with international manufacturing systems, aiding in the successful production of handbags and footwear, and positioning the company for global expansion.

Bestie Kitchen

CSIRO supported Bestie Kitchen through its Kick-Start program, with the support of CSIRO extrusion and product development teams. The collaboration led to the development of natural, therapeutic gummy chews for pets, produced through high moisture extrusion. The team assisted in formulating carrier systems and processing methods to produce microbially safe and stable products incorporating nutraceutical ingredients aimed at enhancing pet health.

Valorising Food Waste

CSIRO developed an innovative method to convert food-grade waste like apple pomace—a nutritious but often discarded by-product of juicing—into shelf-stable, functional food ingredients. This process stabilises the pomace to prevent degradation while preserving its nutritional value, making it suitable for use in powders, flakes, pastes, and pellets across a range of food products including cereals, snacks, smoothies, and baked goods. This approach presents a valuable commercial opportunity for creating sustainable, nutrient-rich products from underutilised biomass.

Dairy, Fruit & Vegetable Snacks

CSIRO supported an international dairy company in developing a model to predict the expansion and texture of dairy and non-dairy extruded snacks. Using CSIRO’s pilot-scale extrusion facility, 88 food-grade snack samples were produced across a range of formulations combining dairy proteins, fruit/vegetable powders, and starches. Key processing parameters were tested and refined, and samples were characterised for expansion, texture, and hydration properties. The project led to a preliminary modelling framework to guide product development by linking formulation and process conditions to microstructural outcomes.