Keynote Speakers

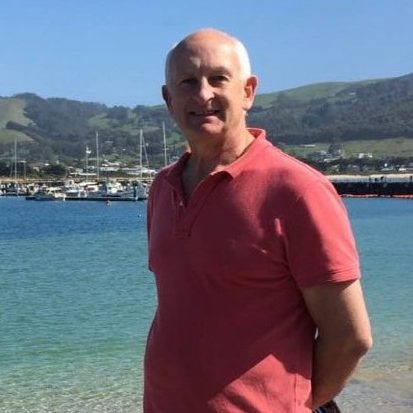

Dennis Forte

Dennis Forte & Associates

Title:

The Evolution of Extrusion Technology

Bio:

A Chemical Engineering graduate of the Royal Melbourne Institute of Technology (RMIT), Dennis Forte spent ten years with the MARS Corporation. During this time he was involved in both Process and Product Development roles within the areas of Confectionery, Canned Petfood and Dry Petfood Extrusion Technologies.

Dennis then spent five years with Uncle Tobys as the Process Engineering Manager, where he was actively involved in the quantification and optimisation of the various unit operations employed in the manufacture of ready-to-eat breakfast cereals and snacks.

His key areas of expertise include Extrusion Processing, Process Modelling, Process Optimisation and Drying Technology. He has published numerous technical papers in various Journals and has authored four text books on Food Extrusion.

Dennis has been practicing as an independent Engineering Consultant to the food industry for more than 20 years, providing technical support, design expertise and training to a broad range of manufacturers throughout Australia, South-East Asia, Africa and Europe.

Azad Emin

nexnoa

Title:

Protein Texturization via Extrusion: Bridging the Past and Future

Bio:

After earning his PhD with highest honors (summa cum laude) in Food Process Engineering in 2013, Dr. Emin completed his habilitation in 2021, receiving the venia legendi in “Biopolymer Extrusion” from the Faculty of Process Engineering at the Karlsruhe Institute of Technology (KIT).

As a research group leader, associate fellow, and Privatdozent at KIT, Dr. Emin has gained international recognition for his pioneering work, demonstrated by his extensive research projects and influential publications in food extrusion technology. In 2021, he was honored with a professorship offer in “Food Process Engineering” from the Technical University of Munich.

Embracing his vision for industry-driven innovation, Dr. Emin chose instead to establish nexnoa GmbH, where he continues to contribute to the future of food process engineering.

Karsten Schellhas

SchellhasFood

Title:

Important Parameters for Producing Hybrid Products

Bio:

Karsten is a Technology Consultant to the Meat and Alternative Protein sector, with over 30 years of experience in meat processing operations and more recently in the past 5 years has experience aiding customers with the development of alternative protein products, particularly in in Canada, USA, and Europe. He is also a 4th-generation German Master Butcher and Sausage Maker, and European-Trained Chef.

Schellhas Food Technology Consultants is a small service-based company specializing in developing new value-added alternative protein products for meat companies small or large, and being a prime conduit for new process technologies and machinery.

Karsten works with CEO’s, VP’s, Owners, Operators & Marketing Personnel to help companies achieve:

- Manufacturing of value-added, quality meat, sausage, and alternative protein products

- Sales/Development of New Innovative Products

- Brand Development & Marketing

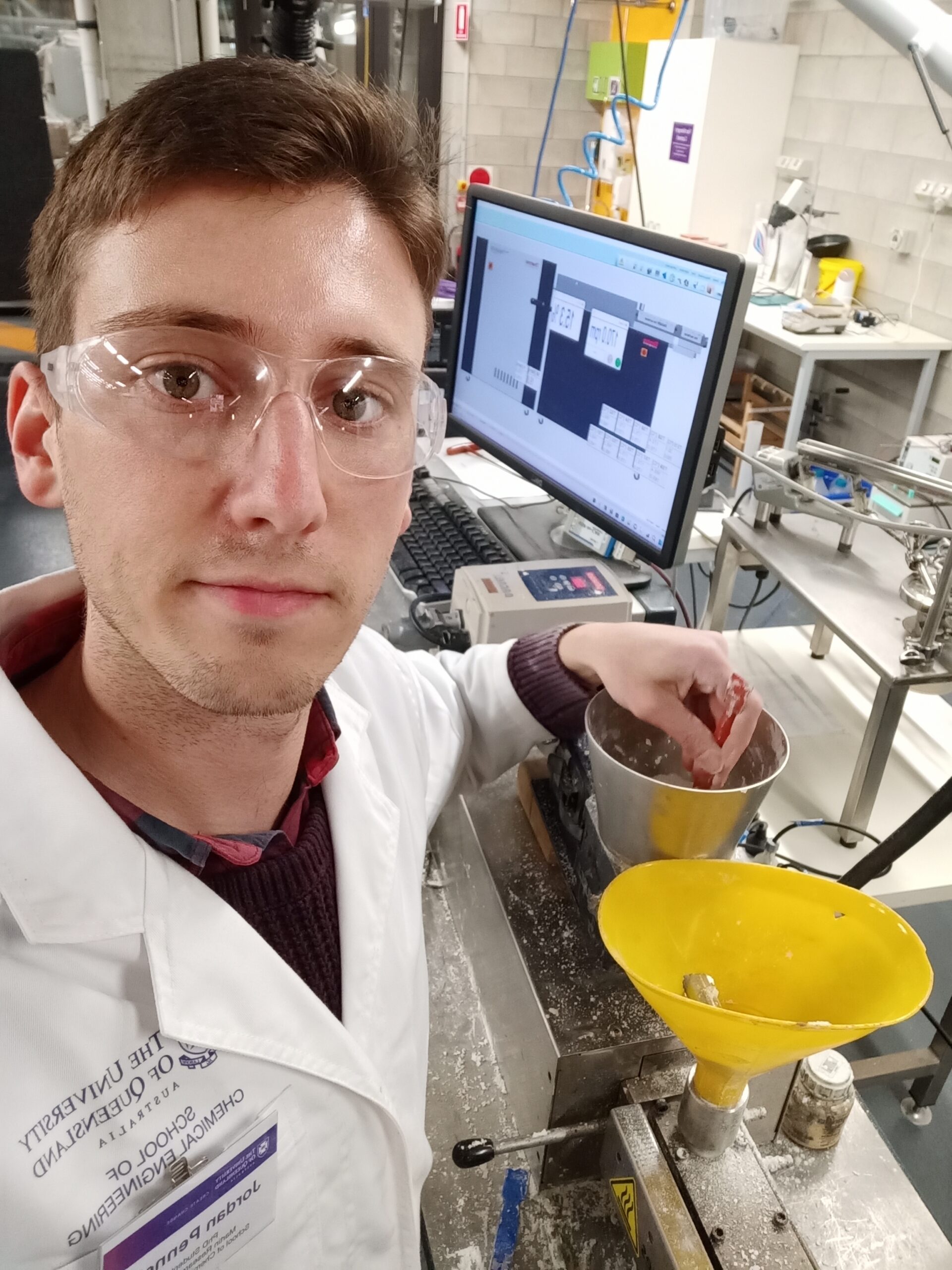

Jordan Pennells

CSIRO Food Program

Title:

AI and Machine Learning in Extrusion Processes

Bio:

Jordan holds dual degrees in Science and Chemical Engineering from the University of Queensland (UQ). He completed his PhD at UQ in 2022 with a thesis entitled “Sorghum as a Novel Biomass for the Sustainable Production of Cellulose Nanofibres”, which explored the quality, sustainability, and statistical variability of biomass-based materials.

Jordan is currently a Postdoctoral Researcher in Food Engineering at CSIRO, where he focuses on understanding the complex material transformations that occur during twin-screw extrusion to produce a wide range of food products, including plant-based meat.

He is now leading the development of CSIRO’s Intelligent Extrusion Platform—a predictive, data-driven system designed to provide a deeper mechanistic understanding of the food extrusion process, optimise process efficiency, and improve product quality.

Osvaldo Campanella

The Ohio State University

Title:

Extrusion Frontiers: From Crunch to Cut – Engineering Plant-Based Foods Across Moisture Realms

Bio: Professor Osvaldo Campanella is the Carl E. Haas Endowed Chair in Food Industries at the Department of Food Science and Technology at the Ohio State University since 2019.

He completed his graduate studies at the University of Massachusetts, where he earned a Ph.D. in Food Engineering. He had academic positions in the Department of Food Technology at Massey University, New Zealand, 1991-1998, the Department of Biological and Agricultural Engineering, Food Science and the Whistler Carbohydrate Center at Purdue University, 1999-2018, where he is now an Emeritus Professor.

Area of Expertise: Food processing engineering, extrusion, rheology, modeling, structure-function of foods and food ingredients, modeling kinetics of microorganism survival and food nutrients during thermal/non-thermal processes.

Peter Hutchinson

ENH LTD

Title:

Evolution & Current Challenges of Extrusion in the Feed Markets

Bio:

Peter Hutchinson is an international consultant specializing in extrusion processing for aquafeed, pet food and specialty applications. With over 25 years of experience, Peter has led the development and commissioning of advanced extrusion systems worldwide. He is the Director of ENH Ltd and Extrusion Co. Ltd and has consulted for major international feed companies. Peter’s work spans board support, plant design, process optimization, R&D, and operator training, with a strong focus on innovation and commercial impact across global markets.

Anneline Padayachee

Dr Anneline

Talk:

Consumer Perceptions of Extruded Foods

Bio:

Dr Anneline Padayachee is a rare hybrid of a food scientist and nutritionist.

A nutritional food scientist.

She busts food and nutrition myths and gives food producers and policymakers the information you need to make educated and panoptic decisions.